Top-class analysis

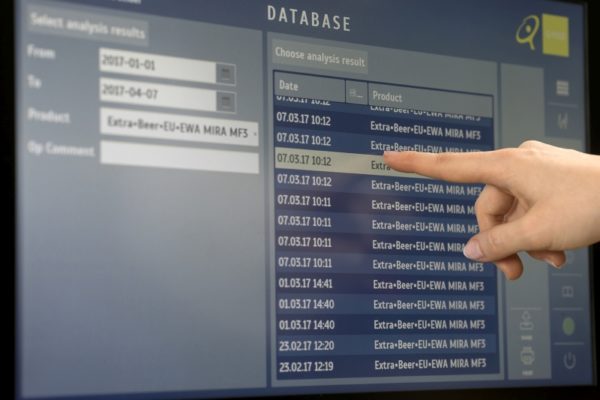

QUANTOS introduces a new, quick and accurate analysis process for the whole production and distribution chain of the food industry into the market.

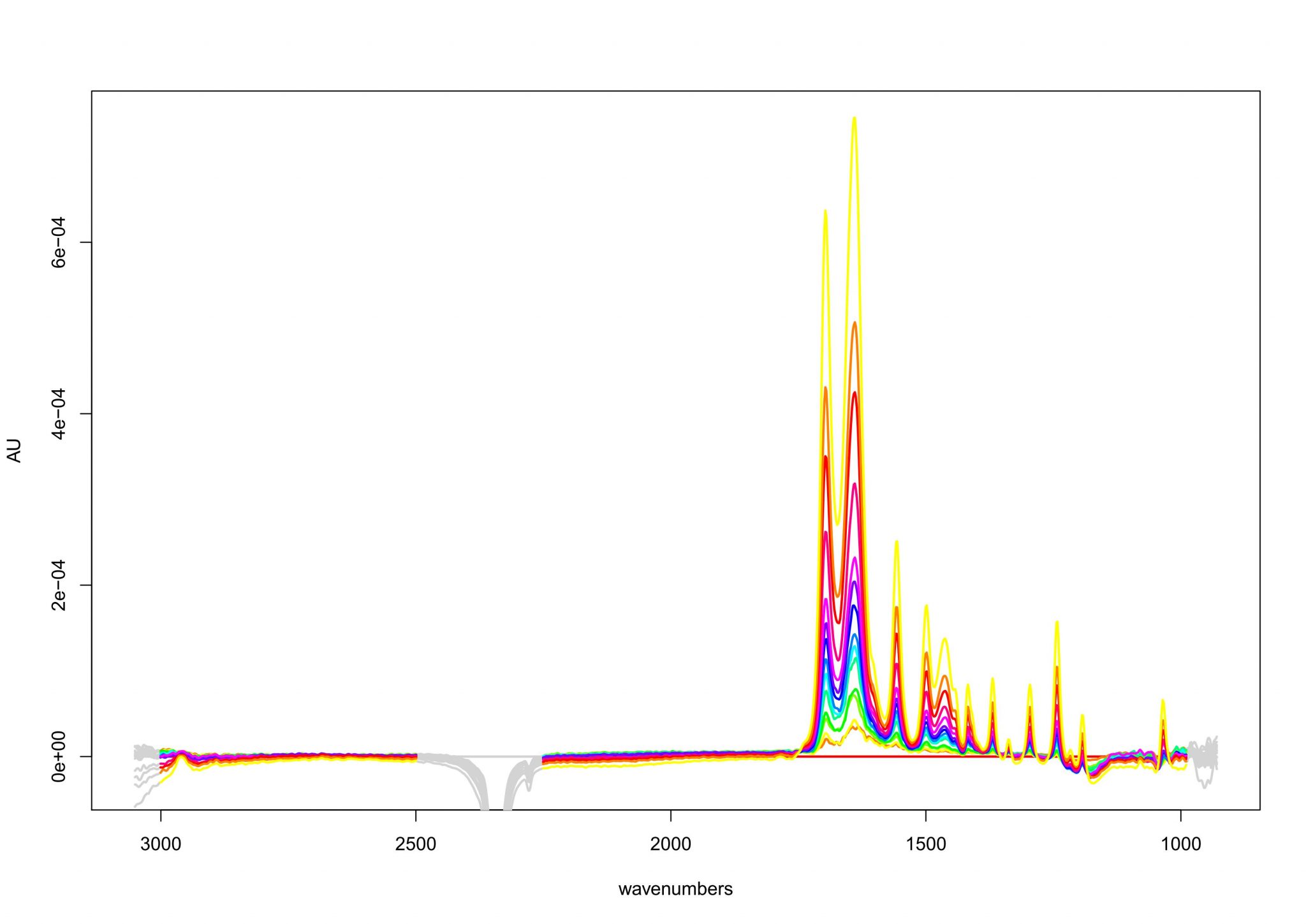

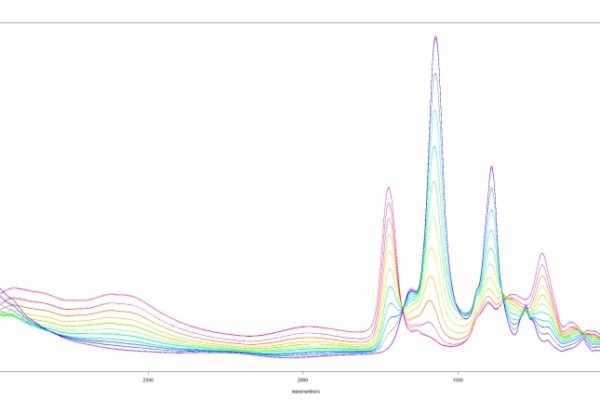

In a single measurement, it analyses the exact concentration of the different ingredients and parameters of a sample – and all in just a few minutes.

QUANTOS sets a new benchmark, both in terms of monitoring and optimising the production chain, as well as of quality control of the end product.