At a glance…

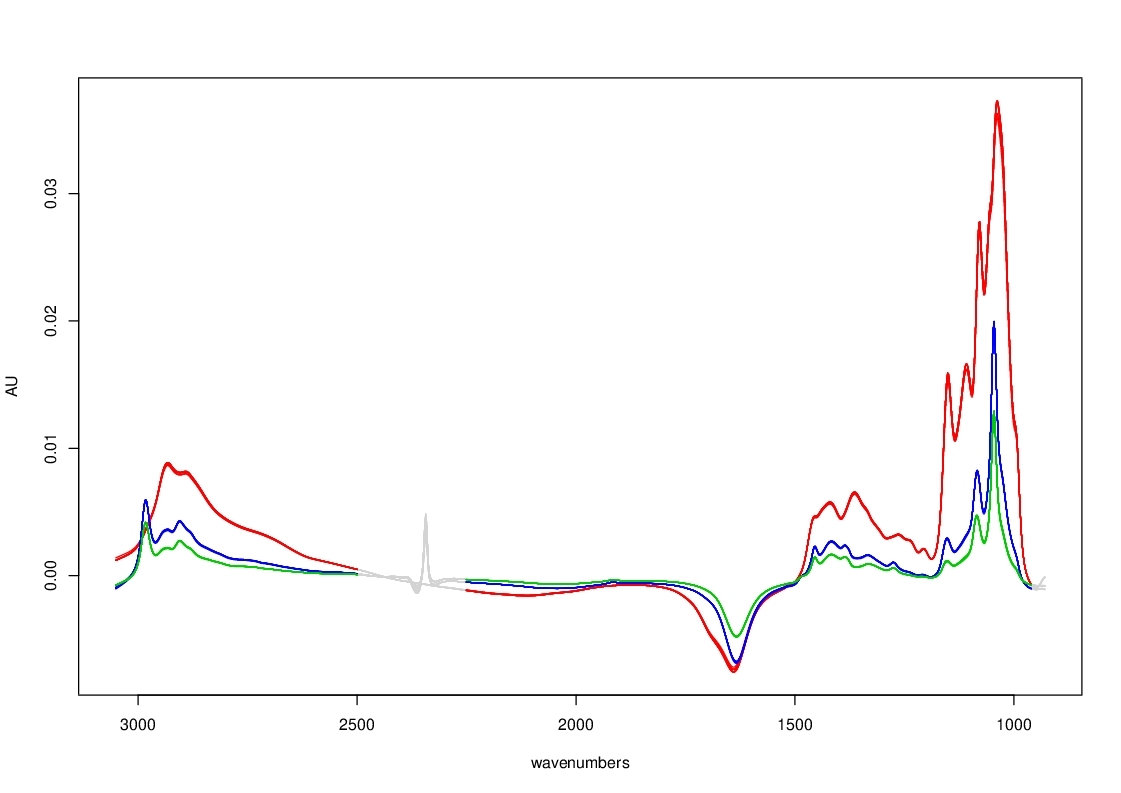

QUANTOS performs quick and precise analyses during the whole production and distribution chain for brewery operations. QUANTOS sets a new benchmark, in terms of both the management options for the brewing process, and product quality control. Each intermediary product and every step of the brewing process can be analysed by QUANTOS and thus optimised. QUANTOS issues an individual digital fingerprint for each sample. This is compared to the reference spectrum in the Beer Base that represents the quality standard for the relevant brewing stage. To determine the quality standard of the end product, the user can measure the quality of all subsequent batches and, of course, also verify that a beer belongs to a particular type. Not only does the analysis identify individual types of beer but the production location and product batch also leave a small but characteristic signature in the digital fingerprint. Due to its comprehensive spectrum of measurable substances, QUANTOS can also analyse beer-mixed beverages as a first quick test.